Turbo pistons and Carrillo rods are weighed and matched.

Turbo pistons and Carrillo rods are weighed and matched.

Custom water pump housings, two sizes. One for the BOLT4 and the other for the H1MAXI V8. The later is larger capacity and has larger ports.

The water pump operates at 7000 rpm when the engine is at redline. It is very efficient producing 48 gpm at 6000 rpm with a back pressure of 6 psi. Most water pumps are rated at a much lower back pressure which inflates their actual capacity. Electric water pumps are particularly sensitive to back pressure.

The water pump operates at 7000 rpm when the engine is at redline. It is very efficient producing 48 gpm at 6000 rpm with a back pressure of 6 psi. Most water pumps are rated at a much lower back pressure which inflates their actual capacity. Electric water pumps are particularly sensitive to back pressure.

Heads and front cam drive assembled, the engine is flipped to begin work on the top end.

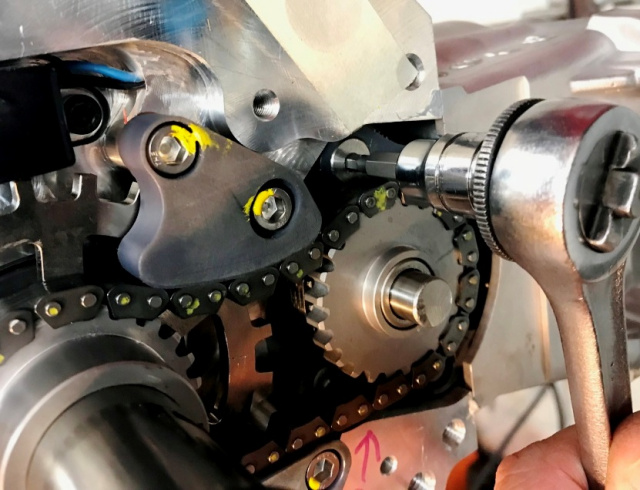

Shown is the installation of the front cam drive. Besides power, a design objective for the H1 MAXI V8 was compact size- keeping the length of the engine to a minimum. Incorporated in the first 34mm from the end of the #1 main bearing are the crank trigger wheel and sensor, offset camshaft drive and guides, and front seal. In the next 54mm are the oil pump drive, alternator drive, front cover and harmonic damper.

Shown is the installation of the front cam drive. Besides power, a design objective for the H1 MAXI V8 was compact size- keeping the length of the engine to a minimum. Incorporated in the first 34mm from the end of the #1 main bearing are the crank trigger wheel and sensor, offset camshaft drive and guides, and front seal. In the next 54mm are the oil pump drive, alternator drive, front cover and harmonic damper.

A sprocket chain drive 1:1 from the crank goes to an intermediate sprockets drive which then accomplishes the 2:1 ratio to the cams. This allows the crank nose to be larger (28mm) in diameter, which was otherwise limited to 22mm on earlier designed engines with direct drive to the cams. The larger diameter nose creates opportunity for substantial power takeoff. Maybe a supercharger?

Below is the front cam drive enclosed with the front engine cover and the protected belt drive to the oil pump. A harmonic damper pulley drives the alternator.

The top blue/black wires go to the internal crank trigger.

The MAXI is readied on the dyno.

RETURN HOME.